Manufacturing & Warehousing: R&M’s modular crane packages are widely used in automotive facilities, metal fabrication shops and general warehouses where uptime and reliability are critical.

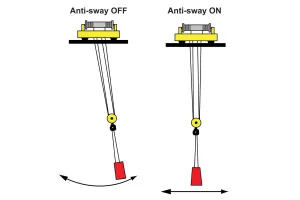

High-Precision Handling: Facilities that handle large, fragile or high-value loads benefit from the ControlMaster Anti-Sway system, which automatically compensates for load swing and increases operator control, making it ideal for costly or delicate assemblies. Additional operator assist features help make the work floor safer and the factory more efficient:

- Follow-me feature aids hand positioning for reduced cycle time

- Automatic hook centering positions the crane hook directly above the load

- Side-pull prevention monitors the rope angle to prevent damage to critical components

- Slack rope protection monitors rope tension and automatically cuts off the hoist's motor when the rope is slack.

- Load restricted area feature allows operators to set defined areas where the crane can only be operated below the rated capacity

- Restricted zones define areas where the hoist may not enter, to avoid machinery or structures.

- Tandem control synchronizes lifting across two hoists so that they can lift a single load as one.

Repetitive Load Transfer: QLP push cranes and QL electric chain hoist cranes offer ergonomic, cost-effective alternatives to jib cranes and forklifts in assembly lines, shipping and packing applications, while offering flexibility for facilities with multiple stations in a single bay.

Heavy-Duty Lifting: Spacemaster® rope hoist packages handle the most demanding weight and duty-cycle requirements with the highest levels of reliability and precision. For extremely high-duty cycle applications, the PDW hoist offers special features such as specialty hooks and provisions for below-the-hook devices, precision load and sway controls or a maintenance platform, giving you a big impact in a compact package.