Standard Features

- 1 - 12.5 ton (1,000 - 12,500 kg) capacities

- Lifts up to 98 ft 5 in (30 m)

- Lifting speed range up to 40/6.6 fpm (12.2/2 mpm)

- 208, 230, 460, 575/3/60 or 380/3/50 power supply

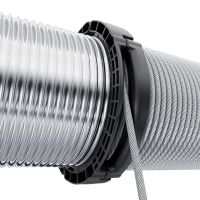

- Single-reeved or double-reeved

- Remote connectivity via modem and OLI app for predictive maintenance and load monitoring

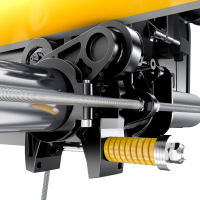

- 2-speed hoisting and inverter-controlled trolley motions for better performance and prolonged equipment life

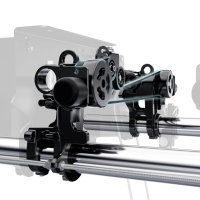

- Compact size and world-class headroom

Why Choose the SXR Hoist?

R&M is proud to introduce the SXR hoist to the well-known Spacemaster line. This innovation in lifting technology combines industry-leading features with key enhancements that address the feedback we’ve heard about its predecessor. This versatile hoist integrates advanced controls, integrated communication via the OLI app and visibility across the entire crane system. Designed with ease of maintenance in mind, the SXR enables cost-effective, high-performance operation for applications across industries and environments.

- Maintenance-friendly, robust mechanical design

- Data-driven maintenance with HoistMonitor® Enclave and OLI Comms network

- Connected features support operator efficiency and safety

- Core of lifting, drive train components are designed and built in-house, specifically for hoisting applications

- Options for tough environments, like synthetic rope, thrust rocker and belt drive

Driven by Data: Made for Operators

The Spacemaster SXR is compatible with a communication protocol, OLI Comms+, to gather data from all the electronic devices on your SXR crane. This creates an ecosystem of information that improves your ability to predict maintenance needs and indicate areas for performance improvement. SXR is available with a wide range of inverter and speed options to meet your needs.

Trolley and Bridge Travel Controls: Inverter controls are R&M’s standard for trolley and bridge travel motions. Inverter controls reduce load swing and eliminate brake wear.

Hoisting Controls: Two-speed hoisting controls are the standard for the SXR. ControlMaster® Edge hoisting inverters offer extended speed ranges and reduced brake wear. ControlMaster Elite hoisting inverter controls offer the same advantages as the Edge inverters, plus expanded smart features and high-precision speed control.

The OLI Comms+ integration also allows for an array of operator assist features, designed to make crane operation safer, faster and easier.

Operator assist features include:

- Follow-Me: Position the crane over the load by guiding the hook by hand for reduced cycle time.

- Hook Centering: Automatically positions the crane hook directly above the load. Faster load cycles and improved ease of operation.

- Side Pull Prevention: Rope angle monitoring automatically prevents lifting if rope angle exceeds 4° from vertical, to prevent damage to critical lifting components.

- Anti-Sway Technology: Prevent and correct any load sway with active counter-movements of the crane. Sway correction is based on active rope angle measurement.

- Slack Rope Protection: Continuously monitor rope tension with automatic cut-off of the hoist motor when slack rope is detected.

- Load Restricted Area: Set defined areas of the factory floor where the crane can only be operated below the rated capacity.

- Restricted Zones: Define restricted zones where the hoist may not enter, for example, to avoid machinery or structures that are on the factory floor.

- Tandem Control: Electronically synchronized lifting across two hoists for precisely lifting a single load in tandem.