Easy to Operate: Our synthetic and wire rope hoists feature ergonomic controllers and smooth operation that reduce operator hand fatigue and improve safety. Variable speed controls provide infinitely adjustable lifting speeds from minimum to maximum capacity, allowing operators to match hoist performance to specific application needs. Advanced control systems, such as anti-sway technology, automatically compensate for load movement and make even complex lifting operations straightforward for operators.

Safe and Reliable: Safety is engineered into every aspect of our rope hoist design. Multiple safety systems work together to protect operators and loads, including redundant braking systems, overload protection and fault supervision that prevents operation when system faults are detected. The HoistMonitor® Enclave system continuously monitors hoist performance and provides real-time data on load conditions, duty cycles and component health to help prevent equipment failure and ensure safe operation. Additional safety features include anti-collision systems, load-turning protection and specialized controls for critical lifts where operators work in close proximity to suspended loads.

Precision Control: Wire and synthetic rope hoists deliver exceptional positioning accuracy through advanced control technologies. Micro-speed controls and inching capabilities allow for precise load placement with minimal operator input, while automated positioning systems can repeat complex movements with millimeter accuracy. Smart controls integrate seamlessly with below-the-hook devices, providing coordinated operation of specialty lifting attachments like magnets, spreaders and vacuum lifters.

Load floating controls suspend loads without engaging the brake, allowing natural settling before final positioning. This precision capability makes rope hoists ideal for applications requiring exact placement, such as assembly operations, die handling and component installation in manufacturing environments.

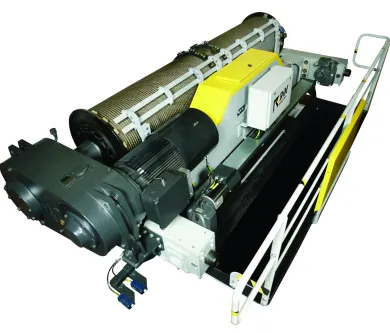

Robust Construction: Built for demanding industrial environments, wire and synthetic rope hoists feature heavy-duty components designed for extended service life. Class H motor insulation provides superior protection against overheating, while specialized IP66 sealing and enclosure systems defend against dust, moisture and corrosive atmospheres. Weather-resistant configurations include rain covers, IP66-rated protection and specialized coatings for outdoor and harsh environment applications.

Our modular crane packages allow customization to specific application requirements, from explosion-proof components for hazardous locations to specialized materials for extreme temperature operations. This adaptability ensures optimal performance across a range of industrial environments.