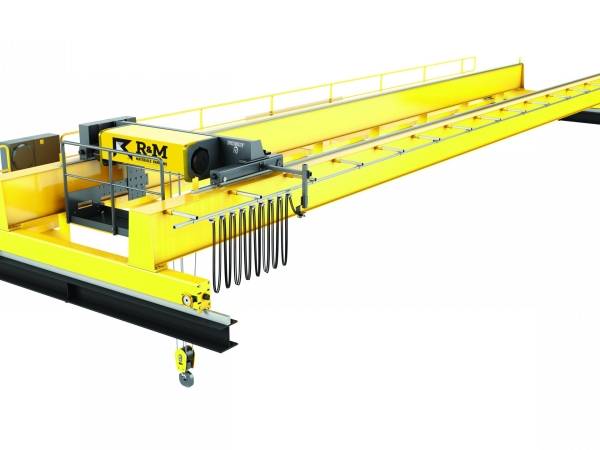

Optimized Hoisting Solutions for the Oil and Gas Industry

Petrochemical plants and refineries keep the world's factories running, homes heated and vehicles moving. Whether operating onshore or offshore, robust hoisting systems tailored to these challenging environments are essential for maintaining seamless operations and meeting regulatory compliance. This critical infrastructure industry can't afford to take risks on refinery equipment that doesn't meet the highest standards, which is why R&M's equipment is designed to withstand the harsh environments associated with the petroleum and gas industry.

Related products

FAQs

Unique Demands of the Oil and Gas Sector

Show

Specialized Offshore and Onshore Hoisting Solutions

Show

Handling Heavy Equipment in Hazardous Environments

Show

Customization for Unique Applications

Show

Case Study: Explosion-proof Crane That Delivers Unquestionable Reliability

Show

Maintenance Programs to Ensure Equipment Longevity

Show