Date: 11/30/2022

Previous Blog: Gantry, Jib & Workstation Cranes

When Does Hook Drift Matter?

Reducing Hook Drift

The job of a crane is to lift heavy loads and to do so quickly and accurately so that valuable time is not wasted on mistakes. When you have projects that require extra precision, hook drift is an important factor to consider when choosing the best hoist for your applications.

Hook drift can be defined as the lateral movement of the hook as the rope unwraps from the drum during the lifting or lowering movements. Hook drift adds additional complexity to the hoist operator's job, especially when precision and alignment are critical. In addition, different applications require varying degrees of precision. This is where drum diameter and hoist reeving type come into play.

Rope Drum Design

The design of a hoist's rope drum may seem insignificant compared to other factors, but it is critical to precision, safety and the end approach on a factory floor.

To achieve maximum performance while reducing hook drift, R&M offers single-reeved hoists with a wide rope drum diameter design, compared to competitor hoists in the market. The wide diameter rope drum reduces hook drift to just 1/8th of an inch per vertical foot of lift, giving operators near-true-vertical lifting accuracy, especially when we consider that most setting adjustments are happening within the last few inches of a lift.

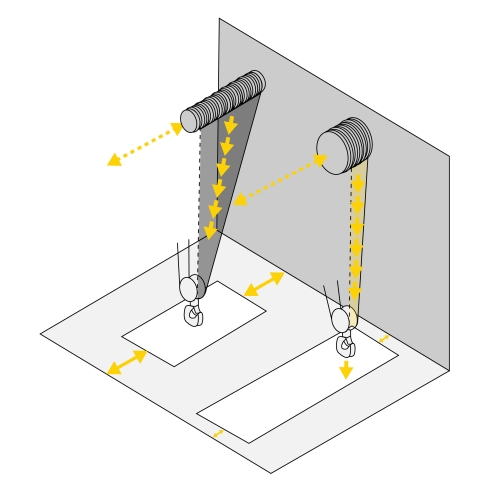

The R&M Spacemaster® SX hoist's wide drum diameter allows for greater lifting heights and more precise operations within a compact, space-saving design. Because R&M's wide diameter rope drum is more compact, end approach is also improved – meaning more workable floor space compared to cranes with hoists that have long, narrow diameter drums. The graphic below illustrates hook drift reduction and improvement in approach when using a wide diameter rope drum vs. a long, narrow diameter drum.

Find Out How Rope Drum Design Can Improve Your Workspace

When Precision Matters

The biggest reason operators need to care about hook drift is that it impacts the timing and accuracy of their picks.

Some applications where precision is critical include:

- Lining up the load: Precision is important in situations where equipment needs to be lined up exactly when lifting or setting down the load, such as in the case of setting a die in a metal-working application.

- Assembly: When a hoist is required to put together two or more pieces as part of the assembly process, precision is required to set pieces down in specific spots, while also avoiding a bottleneck in production. For example, in an automotive application, you may want to place pieces of a car body onto the chassis to build it up. Difficulties in placement of the load can cause production setbacks, damage to the parts and unnecessary wear on the hoist.

- High throughput: When speed matters, operators have less time to make adjustments to their loads. Reduced hook drift makes this process more intuitive, meaning faster throughput for that task.

Single-Reeved Hoist Vs. Double-Reeved Hoist

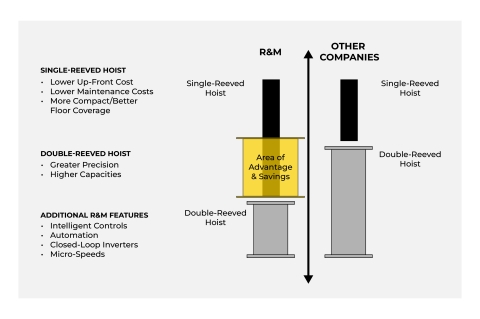

Single-reeved hoists have one wire rope attached to the rope drum, whereas double-reeved hoists use two wire ropes that wrap and unwrap at the same time from a single drum. While a single-reeved hoist cannot offer 100% true vertical lift, R&M's hoist still reduces drift to just 1/8th of an inch for every vertical foot of lift, which is usually more than enough for most applications.

A double-reeved hoist does allow for true vertical lift with no hook drift, but single-reeved hoists save on headroom, reduce initial new equipment costs by 20-25% and offer 40-50% on rope-related maintenance savings. Single-reeved hoisting is therefore preferred from a cost perspective, if the application allows for it.

Single-reeved hoist:

- Lower up-front cost

- Lower maintenance costs

- More compact

- Better floor coverage

Double-reeved hoist:

- 100% precision with no hook drift

- Expanded capacity range

In most scenarios, R&M's single-reeved hoist will cover all of your application's needs due to the extremely low amount of hook drift compared to other single-reeved hoists with a narrower drum and R&M’s broad range of single-reeved hoists. Most applications do not require true vertical lift for precision alone, making it worthwhile to consider the benefits of a single-reeved hoist with lower installation and maintenance costs.

If 1/8th of an inch of hook drift per vertical foot of lift is still not precise enough for your needs, you may need to consider additional features that support your application's needs. These additional features often include electrical features that help to fine-tune the speeds and operation of the hoisting motor for an extremely detailed position of the load. Additional features have the potential to make a significant impact on efficiency and productivity.

Still not sure what type of hoist suits your needs? Find out when you should choose a single-reeved vs. double-reeved hoist.

Customized for Your Needs

R&M's unique hoist design is paired with additional precision features to create the right crane for optimal performance. Some examples of common combinations for improved performance and efficiency are:

High-Capacity Applications

- Hoist Monitoring System paired with the OLI app

- Secondary Hoisting Brake

- Hook Latch Trigger

- Properly Classified Duty Cycle

Long Height of Lift

- ControlMaster® Anti-Sway System

- Class H installation for Hoisting Motor

- Hoist Monitoring System paired with the OLI app

- Properly Classified Duty Cycle

- Slack Rope Supervision

Precision Lifting and Setting

- Closed Loop Inverter Control Hoisting

- Intelligent Controls (micro speeds and inching)

- ControlMaster Anti-Sway System

- Load Turning Features

- Hoisting Synchronization

Hook drift is a problem that is easily reduced while saving on space and costs at the same time. Do you want to ensure you have the right hoist to run your operations smoothly? Call us at 800-955-9967 or contact us online to speak with an expert about your options and which additional features are right for you.