Boosting Productivity with Custom Hoisting Solutions for Manufacturing

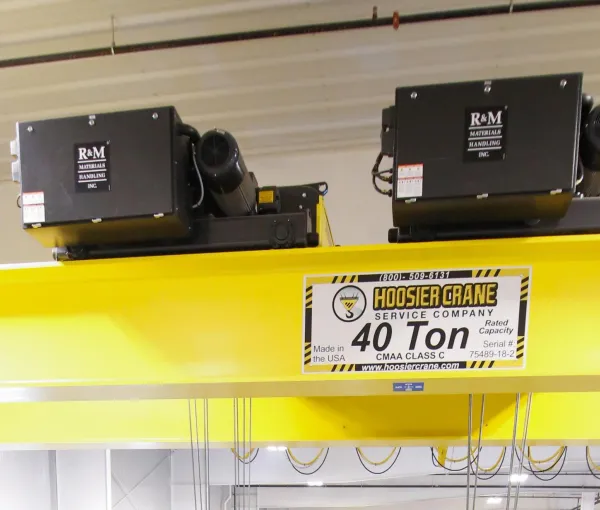

No matter what you manufacture, the reliable lifting equipment you need can be found at R&M Materials Handling. From light-duty to heavy-duty performance, we utilize new technology to help you improve the safety and efficiency of your operations. Centrally located with a distribution network that reaches North America, Central America and South America, we take pride in providing accurate and timely delivery.

Learn how R&M manufacturing equipment can keep your operations running smoothly. Whether you’re lifting heavy machinery components or handling delicate equipment, the right crane system can help you stay ahead of the curve.

General Manufacturing

Manufacturing has experienced sustained growth over the last few years, and like any growing industry, it faces challenges. Keeping the line flowing means precise timing, with all parts working at capacity. Any interruption can affect productivity and profitability. The right lifting equipment can help you keep your line running and minimize costly downtime.

Expertise and Innovation

At R&M, we leverage our 90+ years of experience combined with dedication to innovation to help your operations run smoothly while reducing the total cost of ownership (TCO) of your hoists and cranes.

- Component Design

- IoT/OLI/Predictive Maintenance

- Modular Crane Packages

- Local Crane Builders and Service Networks

Why Choose R&M Materials Handling?

The relationship between cost drivers and the key pillars of TCO often influences your direct and indirect lifetime costs. Our safety standards, dependability and preventive/predictive maintenance work together to increase production time, reduce unplanned downtime and prevent breakdowns that cause costly delays.

At R&M, our goal is to help you keep your line running as efficiently and cost-effectively as possible. We offer a set of products and features that can be customized to your specific needs without time constraints and the cost of one-off engineering.

Related products

The Importance of Versatile Lifting Solutions in Manufacturing

Common Applications of Hoists and Crane Systems in Manufacturing

Types of Hoists and Cranes for Factory Operations

Integrating Automated Systems with Hoisting Equipment

Customization for Specific Manufacturing Processes

Safety Features that Reduce Workplace Risks

Case Study: Unique Factory Increases Efficiency Thanks to R&M Overhead Cranes

Best Practices for Maintenance and Preventing Wear and Tear

By investing in the right hoisting equipment — customized to your manufacturing needs and maintained using best practices — your facility can increase productivity, reduce costs and secure a competitive edge in today’s demanding market. Let us help you design a flexible, reliable hoisting solution that scales with your manufacturing operations.

Use our Crane Designer tool to get a custom recommendation - or contact us directly to speak with an expert about your facility’s needs.