Date: 4/21/2023

Previous Blog: Environmental Impact & Sustainability

How Safety, Productivity and Maintenance Create Lifetime Value

It’s not surprising that short-term savings are a primary concern for most companies. However, when it comes to equipment such as hoists and cranes, the best way to determine if you are saving money is to look at the lifetime value or total cost of ownership (TCO). Using this model, you can assess all costs over the life of your equipment, taking into consideration challenges, risks and even predicting unknown variables.

Three Key Pillars of Total Cost of Ownership and Lifetime Value

Understanding the overall cost of your equipment benefits your project by producing a better return on investment (ROI) and improved performance. Keeping TCO as low as possible is the reason so many businesses fret over the dreaded “repair-or-replace” decisions when it is time to replace failing equipment. R&M’s cranes and hoists are built with three key pillars -- safety, productivity and maintenance -- in mind to ensure a lower total cost of ownership.

Safety

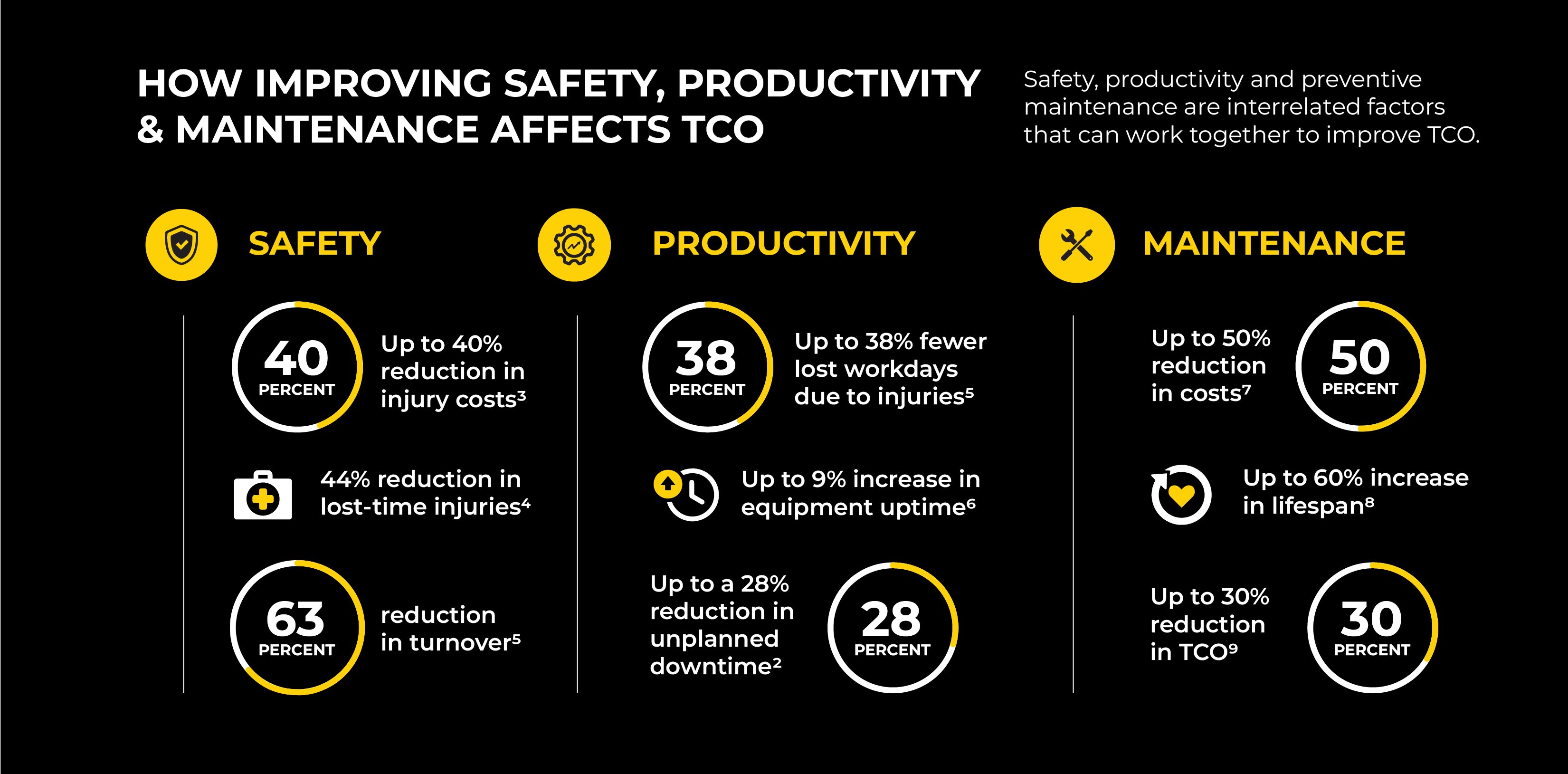

Cranes are one of the most potentially risky parts of a manufacturing facility, which is why crane safety is so vital. Accidents that cause damage to workers and property can be complicated for everyone involved, and even when no one is hurt, the potential costs following an incident are huge.

The cost of any accident, no matter how minor, is substantial. For example, an accident can result in downtime, lost productivity and increased liability costs, all of which can add up to significant expenses. On the other hand, investing in proper crane safety measures, such as regular maintenance and inspections, safety training for operators and workers and implementing safety protocols and procedures can help prevent accidents, reduce downtime and minimize liability costs.

Safety is critical for increasing the lifetime value and reducing the TCO of cranes and hoists. By prioritizing safety, you can protect your employees and equipment, reduce expenses and increase profitability in the long run.

Productivity

Unexpected downtime can decrease the productivity of your business, leading to reduced efficiency and increased operating costs. During the downtime, the crane is not performing its intended tasks, and neither is your crew. This results in lost revenue and decreased profitability. It can also increase maintenance and repair costs, as the crane may require more frequent or extensive repairs to address unexpected issues.

Furthermore, when a crane experiences unexpected downtime, it may be subjected to additional wear and tear, which can reduce its overall operational life. As a result, the crane may need to be replaced sooner than expected, leading to additional capital expenses and decreasing the lifetime value of the crane.

Preventative maintenance and regular inspections to detect potential issues can reduce the risk of unexpected downtime and minimize the associated costs, improving a crane's overall TCO and lifetime value.

Maintenance

Preventive maintenance can help keep the crane in optimal condition, ensuring maximum productivity, efficiency and longevity. By detecting and addressing potential issues early, preventive maintenance can help minimize the risk of more extensive and expensive repairs. It can help prevent breakdowns and unexpected downtime, reducing the risk of costly repairs and replacement.

In addition to preventing unexpected downtime, regular and preventive maintenance can improve crane efficiency and productivity. Keeping a crane well-maintained can also extend its working life, providing greater value over time and reducing the need for premature replacement. You can maximize the lifetime value of your cranes and minimize operating costs while maximizing your return on investment.

Click here to view our Total Cost of Ownership Guide

How R&M Improves the Lifetime Value of Your Hoists and Cranes

Our products are built with safety, productivity and maintenance in mind. With modular crane packages tailored to your needs, you get a smoother, safer and faster installation without the need for one-off engineering. Our HoistMonitor® Enclave records valuable data such as active faults and warnings then broadcasts to the cloud through the IoT gateway. The Overhead Lifting Information (OLI) app accesses this information through iOS or Android devices so operators can view data displayed in a professional, intuitive format. Packaged together, these tools provide real-time information for your operations, leading to increased uptime and improved performance.

Are you interested in talking to a crane expert about optimizing your next project? Call us at 800-955-9967 or visit us online to find a local distributor to help you.